Gaging Stations

FASTATION

Systems improve measurement speed, accuracy and GR&R results dramatically!FASTATION MEASUREMENT SYSTEMS:

- Ideal for SPC

- All GR&R less than 20%

- Other system configurations available based on review of part prints

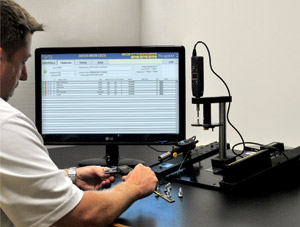

FinalCheck™

One person does the work of three!

Users of the FinalChek System can inspect fasteners and record results approximately three times faster than those using hand-held gages and hand writing inspection results. This state-of-the-art approach enables one person to do the work of three using older equipment and methods. Users input a given part’s inspection requirements into the computer only one time. When inspecting the part after this, the inspector only enters the part number and the system is ready for inspection to begin. Eliminating the need to input inspection requirements every time is one of the major sources of time savings provided by this system. Inspection results can be saved by part number and/or by vendor for future reference. This makes record saving more efficient. It also allows the user to develop a vendor rating program. Vendors who know they are being monitored and rated generally perform better than those who do not. Professional-looking inspection records can be generated immediately after testing or at a future date. Most customers view computer-generated inspection reports as more credible than those hand written or typed. The saying “time is money” is still valid. FinalChek Systems provide users financial savings by greatly reducing inspection and record keeping time.Turn-Key Inspection System with N-Spekt© Software

FinalChek PC Gaging System Includes:

Computerized Data Collection System

- PC Computer

- SVGA Color Monitor, Printer

- Gage Interface with Four Ports & Foot Switch

- Gage Cables

- Operating Software

- N-Spekt© Inspection Software (Windows)

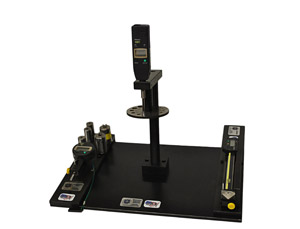

Gaging System E (screws and bolts only)

- Position 1 RecessCheker®

- Position 2 DIMENSION-ALL®

- Position 3 X-120® Adjustable Tri-Roll Gage, or

- X-180® Segment Gage

- Position 4 Length Gage, 0-6″

Gaging System El (screws, bolts and nuts)

- Positions 1 through 4, same as System E

- Position 5 Bi-Point® Internal Thread Gage

Note: All gages mounted on one metal base plate.

Gaging Accessories (sold separately)

- RecessCheker® Elements

- X-120® Templates, Gaging Rolls and Setting Plugs

- X-180® Segments and Setting Plugs

- Bi-Point® Gaging Fingers and Setting Rings

RecessCheker, X-120, Bi-Point and DIMENSION-ALL are registered trademarks of Greenslade and Company, Inc.